AN AFFORDABLE AND POSITIVE SOLUTION TO PLASTIC WASTE

Plastron Solutions has developed an efficient system that turns plastic waste into fuel. Efficient at low temperatures, requiring a small installation investment in comparison to competitors, and with a low environmental impact, our technology is positioned to help waste processors eliminate plastic waste.

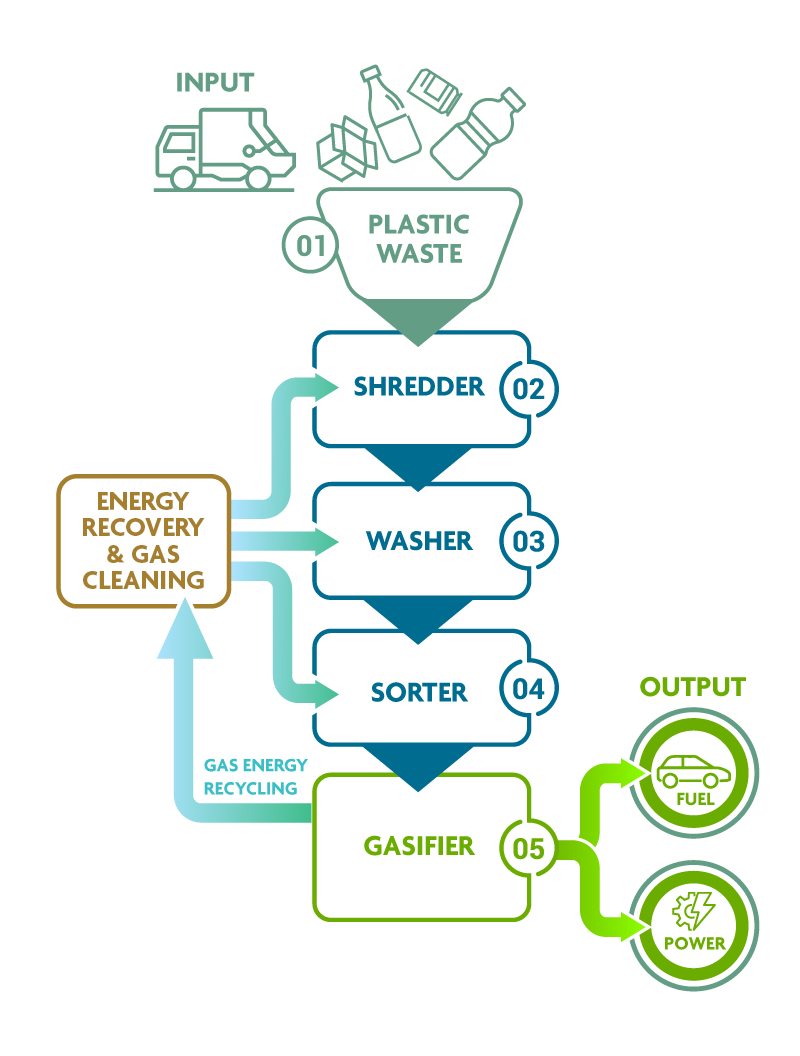

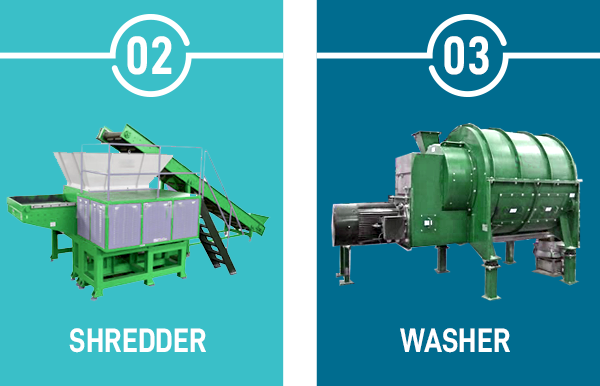

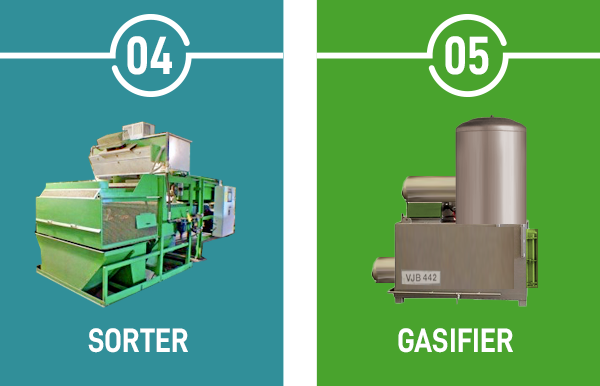

Our system takes raw plastic waste, shreds it, sorts it and pyrolyses it, then further process it into fuel, which can be used for vehicles, heat or to generate electricity. The toxic chemical additives within most plastics are utilised along with the non-recoverable gasses to produce energy that helps run the plant – making it self-powering and reducing its environmental footprint. Each Plastron module can convert up to 8 tonnes of plastic waste a day into up to 3,500 litres of pyrolysis oil and up to 3 tonnes of recyclable plastic flakes, producing approximately 1 million litres of fuel each year, and removing more than 2,400 tonnes of plastic from the planet.

Our system can complement the large-scale, expensive waste-to-energy plants that handle a wide variety of waste forms. With each module requiring only 100 m2 of space, excluding holding tanks for the fuel produced, the Plastron solution is relatively compact.

Who are Plastron’s units designed for?

Councils

Government

Disaster relief

Army

Recyclers

Communities

WATCH OUR INTRODUCTORY VIDEO

THE BENEFITS OF PLASTRON OVER OTHER SYSTEMS

100% Australian Designed.

100% Australian Made.

100%. Australian Proud.

GAME-CHANGING TECHNOLOGY

Plastron’s Solution is striving to be one of the most efficient, environmentally conscientious, and affordable plastic waste processing units on the market.

Turns most plastic waste into usable fuel, heat and/or electricity

Low emissions

Units can be adapted to deal with the hard to process plastics like PVC

Little or no additional energy required once the unit is operating

Small and mobile (2 containers per module site)

Low plant and operation costs

WHAT ARE THE OPTIONS FOR PROCESSING PLASTIC WASTE?

| TRADITIONAL METHODS |

|---|

| METHOD | PROS | CONS | |

|---|---|---|---|

|

LANDFILL The most commonly used practice since the advent of waste collection |

|

|

|

INCINERATION From simple burn-off of waste to highly sophisticated Waste to Energy production |

|

|

|

REPURPOSE Plastic waste is collected and re-used to make new products. |

|

|

|

WASTE TO ENERGY Plastic waste is returned to usable energy |

|

|

|

PLASTIC TO FUEL PYROLYSIS Plastic waste is returned to usable synthetic fuel. |

|

|

| THE PLASTRON SOLUTION |

|---|

|

|

Plastic waste is returned to usable synthetic fuel |

|

|

|---|

THE STORY OF PLASTRON

Our journey started in 2011 when entrepreneur Todd Tulk started developing a more efficient and profitable way to process plastic waste. He spent six years working with leading chemical and electrical engineers to produce the Plastron One, a prototype that successfully produced ‘near-diesel’ oil from dirty plastic waste.

In 2019, Plastron was joined by Macpac founder Bruce McIntyre, who helped the company raise $240,000 for an independent assessment of the prototype. They commissioned the engineers at Kemplant Pty Ltd to perform a comprehensive techno-economic feasibility study of the Plastron Solution. The report and accompanying laboratory tests confirmed the feasibility of the Plastron design and the market report quantified how Plastron fits within the market whilst combating the scale of the existing plastic waste problem.

We have now entered the commercial market and are negotiating contracts for potential sites for the Plastron One.

MEET THE EXECUTIVE TEAM

PLASTRON INSIGHTS

PLASTIC TO FUEL – A GLOBAL SOLUTION

There is a solution to the global plastic pandemic . . . turn it into fuel. Todd Tulk, inventor of Plastron's technology, says this is no pipe dream. It’s a solution available now, which can potentially eliminate plastic waste from a world that is, almost literally, drowning in [...]

The effective plastic-to-fuel solution revolution

As part of our new strategy and rebrand initiative, we are launching a new website. Here you can see an overview of our company, understand a bit more about our revolutionary plastic-to-fuel recycling system and see how we are committed to reducing plastic waste to zero by 2035! [...]

Know your plastic waste footprint

Australians use about 130 kg of plastic per person every year of which only 9% (12kg) of that is recycled. Add to this that upward of 130,000 tonnes of plastic gets dumped into our waterways and into the ocean.

Explaining the Plastron process

Each of our Plastron modules can annually process over 2,400 tonnes of most types of plastic found in municipal waste. This includes waste that which would otherwise traditionally have to go into landfill. https://youtu.be/37BMEZkHanc

New WWF research identifies problem plastics

New research from the World Wildlife Fund has revealed Australians create almost 3 times the global average of plastic pollution each year (19million pieces of plastic and 1.6million plastic bottles end up in our oceans every day). They have identified the 6 most problematic plastics, all of which [...]

Transitioning to a lower carbon economy

We all know that recycling is the right thing to do but, now that China has stopped taking our waste, the Australian government and recycling industries are scrambling to come up with strategies to reduce the amount of plastic we are sending to landfill. [...]

CONTACT US TO FIND OUT MORE

Please feel free to contact us to discuss your project requirements or to find out more specific information about the Plastron system.